The quest for faster, safer, and more fuel-efficient aircraft is a driving force in the aerospace industry. A critical element in achieving these goals is the material used in construction.

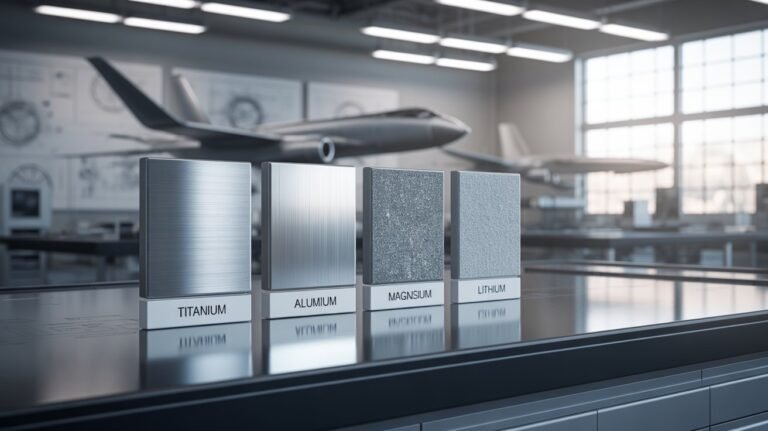

Lighter aircraft consume less fuel and have a smaller environmental footprint, making the selection of materials a pivotal aspect of modern engineering. This guide explores four essential lightweight metals that are shaping the future of next-generation aircraft.

1. Titanium Alloys

Titanium has long been a prized material in aerospace for its exceptional strength-to-weight ratio, impressive corrosion resistance, and ability to withstand extreme temperatures. While heavier than aluminum, its superior strength allows engineers to use less material, resulting in components that are both lighter and more durable. A prime example is the Lockheed Martin F-22 Raptor, which incorporates a significant amount of titanium in its airframe to handle the intense heat and stress of supersonic flight.

Next-generation aircraft are increasingly using advanced titanium alloys, such as Ti-6Al-4V, particularly in critical structural components like landing gear, engine parts, and fasteners. The development of new manufacturing techniques, including additive manufacturing (3D printing), is making it more cost-effective to produce complex titanium parts, further expanding its application in aerospace design.

2. Aluminum Alloys

Aluminum has been the workhorse of the aviation industry for decades, and its role is far from over. Modern aluminum alloys offer an excellent balance of low density, high strength, and formability, making them ideal for constructing fuselages and wings. The primary advantage of aluminum is its cost-effectiveness and ease of manufacturing compared to other lightweight metals.

Innovations in alloy development have led to the creation of advanced aluminum-lithium alloys, which are significantly lighter and stiffer than their predecessors. For example, the Airbus A350 XWB utilizes these advanced alloys to reduce overall weight and improve fuel efficiency. The ongoing evolution of aerospace aluminum ensures it remains a competitive and essential material. Engineers can now select from a wide range of specialized alloys tailored to specific performance requirements, from high-strength applications to those requiring superior fatigue resistance.

3. Magnesium Alloys

Magnesium is the lightest of all structural metals, boasting a density that is approximately two-thirds that of aluminum. This characteristic makes it highly attractive for applications where every gram counts. Historically, its use was limited due to concerns about corrosion and flammability. However, recent advancements in alloy development and protective coatings have largely overcome these challenges, paving the way for its increased use in modern aircraft.

Magnesium alloys are now being integrated into various interior components, such as seat frames, electronic housings, and gearbox casings. By replacing heavier materials in these non-critical structural areas, manufacturers can achieve significant weight savings. For instance, using magnesium alloys in seating can reduce the weight of a single aircraft by hundreds of pounds, directly contributing to lower fuel consumption and operational costs over the aircraft’s lifespan.

4. Metal Matrix Composites (MMCs)

Metal Matrix Composites represent a cutting-edge class of materials that combine a metal (like aluminum or titanium) with a reinforcing material, such as ceramic particles or fibers. The result is a hybrid material that possesses the best qualities of both its components: the lightness and ductility of the metal, and the strength and stiffness of the reinforcement.

MMCs offer performance characteristics that are often unattainable with conventional metal alloys alone. For instance, aluminum reinforced with silicon carbide particles exhibits significantly higher stiffness and wear resistance while maintaining a low density. These advanced materials are being explored for use in high-performance components like brake rotors, actuator pistons, and certain structural supports where conventional metals might fail or add excessive weight. While currently more expensive to produce, the continuous improvement in manufacturing processes is making MMCs an increasingly viable option for next-generation aircraft seeking unparalleled performance and efficiency.